Duplex Basket Strainer vs. Simplex: Which Filtration System Fits Your Pipeline Needs?

Every pipeline faces the same quiet threat. Tiny particles move through the system and slowly wear it down. Over time, that damage affects fluid flow, raises pressure drop, and weakens critical parts. This is why strainers offered in modern pipelines play such a vital role in Duplex Basket Strainer vs. Simplex. They help remove solid particles before those materials reach pumps, valves, and sensitive equipment.

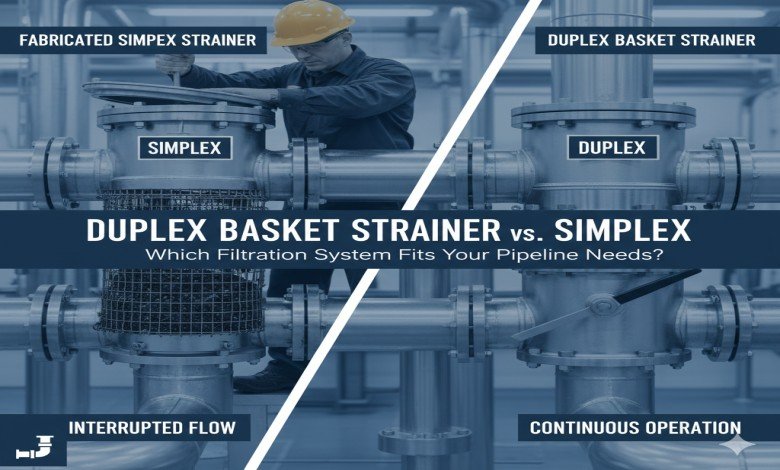

Choosing between simplex and duplex strainers changes how your entire operation runs. A fabricated simplex basket strainer keeps things simple and easier on the budget, while a duplex strainer helps your system stay steady with uninterrupted flow. Once you see the difference, you can choose what fits the way your operation runs.

Choosing the Right Option for Your Filtration System

You may not see them, yet solid particles move through your pipeline every day. Those particles travel with liquids used in chemical processing, oil and gas, and water treatment. When they reach equipment, they scratch surfaces, block passages, and reduce efficiency. That is why filtration never feels optional.

The choice between simplex basket strainers and duplex strainer systems often decides whether your pipeline runs smoothly or faces frequent interruptions. Each design deals with debris and pressure drop in its own way, which also changes how often you need maintenance. Once you get how they work, it becomes much easier to keep your system running the way you want.

How Simplex and Duplex Strainers Filter Fluid

Both designs aim to do one job well. They remove solid particles from moving liquid. Yet their construction changes how they behave in daily use.

A fabricated simplex basket strainer uses a single basket inside a single chambered body. Fluid enters the housing, flows through the strainer baskets, and exits clean. This design works well due to their simpler design, which keeps the system easy to install and maintain.

A duplex strainer uses two baskets in a shared housing. One basket filters while the second stays on standby. When debris fills one basket, you shift fluid flow to the other without stopping the system. That feature supports continuous operation, even during cleaning.

Why Fabricated Simplex Basket Strainers Still Matter

Many pipelines still rely on a fabricated simplex basket strainer because it fits systems that operate in cycles. Batch processes often include planned pauses, which makes cleaning a single basket practical. During those pauses, operators remove debris, rinse the basket, and return the system to service.

These systems also provide a cost-effective solution for operations that do not require nonstop movement. Fewer parts and a single chambered body keep installation and upkeep simple. For many teams, that simplicity feels dependable and familiar.

However, as debris builds, pressure drop increases. That rise eventually forces a shutdown. While this works well for batch systems, it becomes a challenge when pipelines need steady movement.

Why Duplex Strainers Support Continuous Operation

A duplex strainer changes how you manage filtration. Instead of stopping the system, you rotate flow between two baskets. One basket keeps filtering while the other gets cleaned. This design preserves uninterrupted flow, even as debris accumulates.

That steady movement supports chemical processing, oil and gas, and water treatment, where stopping a pipeline disrupts production. When fluid flow remains stable, pumps and valves face less strain. The system also avoids sudden spikes in pressure drop, which helps protect sensitive components. Over time, that stability improves both performance and reliability.

How Pressure Drop Shapes Filtration Choices

Pressure drop tells you how hard your system works to push fluid through a strainer. As debris fills a single basket, resistance rises. In simplex basket strainers, that rise continues until you stop the system for cleaning.

A duplex strainer prevents that problem. When resistance increases, you switch to the clean basket. Fluid flow stays steady, and the system avoids disruption. That steady pressure protects seals, pumps, and downstream equipment. This control becomes especially important in high-volume systems that depend on consistent performance.

How Valves Benefit from Proper Straining

Strainers protect more than just pipelines. They also guard critical valves.

A butterfly valve needs clean liquid to open and close smoothly. When debris reaches it, the sealing surfaces wear down. A check valve also depends on clean flow, since trapped particles can prevent it from closing properly. Both valves perform better when strainers offered upstream continue to remove solid particles without interruption.

A duplex strainer always keeps that protection active, which extends valve life and reduces unexpected failures.

Which Strainer Fits Your Operation

The right choice depends on how your pipeline runs. Simplex basket strainers suit systems that pause regularly, such as batch processes. They deliver reliable filtration at a lower cost, making them a trusted cost-effective solution.

A duplex strainer fits pipelines that never stop. It supports continuous operation, keeps fluid flow steady, and controls pressure drop more effectively. That consistency proves valuable in demanding industries.

Both designs filter well. They simply serve different operating realities.

Conclusion

Every pipeline follows its own rhythm. Some move in cycles, while others never slow down. A fabricated simplex basket strainer offers simplicity and affordability for systems that allow downtime. A duplex strainer helps keep things moving when your line cannot afford to slow down, so you do not have to worry about surprise stops.

When the strainer fits the way you actually run your line, your valves stay in better shape, the fluid flow feels steadier, and the pressure drop does not keep creeping up. Everything just runs with less trouble.

FAQs

What is a duplex strainer?

A duplex strainer uses two strainer baskets in one body. One basket filters while the other waits. You switch between them to keep uninterrupted flow and avoid pressure drop.

How does a fabricated simplex basket strainer work?

A fabricated simplex basket strainer uses a single basket inside a single chambered housing. It removes solid particles from fluid flow, yet it needs shutdowns for cleaning.

Why do butterfly valve systems need strainers?

A butterfly valve stays reliable when strainers remove solid particles. Clean fluid prevents wear, sealing problems, and sudden pressure drop across the valve.

When does a duplex strainer fit best?

A duplex strainer fits continuous operation systems. It works well in oil and gas, chemical processing, and water treatment, where uninterrupted flow protects equipment and keeps processes stable.

How does a check valve benefit from strainers?

A check valve works better when strainers offered in the line remove debris. Clean fluid prevents sticking, backflow, and damage during changing fluid flow.